Drum pumps Techni-flow

pumps@techni-flow-pumps.com

The applications for drums pumps are numerous and correspond mainly to solving the many safety issues of transferring fluid that can be dangerous for people.

These hazards can be caused by accidental contact with the fluid, was accidental breathing fumes, gageuses generated by the fluid.

To meet all these different demands, we have used different pumping technologies:

centrifugal drum pump: for low viscosity fluids.

Displacement drum pump:

for medium to extreme viscosities.

Sanitary drum pumps

Sanitary drum pumps are suitable for emptying drums of food fluid of practically any viscosity:

Centrifugal drum pumps for viscosities up to 800 cps:

fruit juices, food coloring, etc.

The diaphragm pneumatic drum pumps are suitable for fluids with a viscosity of 3000 to 15000 cps.

For higher viscosities we offer pneumatic piston pumps with plunging rod for viscosities up to 30,000 cps.

For food fluid with a viscosity between 30,000 and 500,000 cps, drum pumps with follower plate are essential.

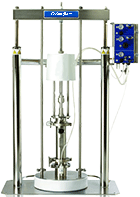

Piston drum pumps for viscous products

Drum pumps for thick fluids are mainly pneumatic pumps.

For fluids of medium viscosity, the empty barrel pumps with a plunging rod will be able to pump products up to 30,000cps.

For pasty products of higher viscosity up to 1,000,000 cps, the pneumatic piston pumping unit mounted on an elevator, with follower plate will be suitable.

Operating principle of drum pumps:

Drum empty pumps are primarily designed from a dip tube of a length to suit major sizes of commercial drums.

The tube empties barrels and passes through an axis which actuates a turbine which is located at the base of the tube.

The material of the tube is chosen to be chemically compatible with the type of chemical fluid to be pumped, as well as the motor shaft and either stainless steel or hastelloy depending on the desired chemical compatibility.

Emptying Glycerin Drums in the Tobacco Manufacturing Industry:

Glycerin is used in the tobacco industry as a texturizing agent, humectant and humidifying agent for tobacco.

In the tobacco manufacturing process, glycerin is stored in closed drums with 2 bungs.

the glycerin used is a food grade glycerin, with a viscosity of 1400 cps, the drum pump used must correspond to the directives of the VDA standard.

For this drum unloading application, we offer a pneumatic membrane drum pump TFG200STF-FDA.

This pump for empty food barrels will continuously feed a tobacco packaging machine which operates at a variable rate and therefore consumes more or less volume of glycerin.

In this application, the barrel emptying pump is permanently supplied with pressure, the pump will accelerate or slow down directly according to the speed of the tobacco packaging machine, without any additional automation.

This drum pump must be maintained in an irreproachable sanitary condition and regularly the pneumatic drum pump TFG200FDA can be dismantled without tools by the operator. In addition, regular disassembly allows a visual check of the state of wear of the membranes so as to change them preventively before a possible failure.

This preventive operation prevents contamination of the pneumatic control part, and speeds up the maintenance operation

Barrel pump for car garage.

In automobile repair garages, the fluids to be handled correspond to small pumping volumes, but in a repetitive manner which impairs the speed of intervention, generates unnecessary fatigue and is a source of pollution.

Car garages are increasingly storing all fluids in a room suitable for this purpose in a centralized manner.

The various drums are equipped with a drum pump, each connected to a network which distributes the fluid in all the workshops.

For these centralized pumping applications, turbines for empty high pressure drum pumps are used to combat pressure loss due to length.

Drum pump for stripping workshop.

The operations carried out in the stripping workshops are numerous and depend on the type of industry in which the stripping workshop operates:

Stripping workshop for renovation of old furniture.

Stripping workshop for bodywork preparation before painting.

Stripping workshop for surface preparation of metals.

In this type of workshop, empty drum pumps are used on the one hand to safely apply pickling fluids to the parts to be treated, and on the other hand to carry out transfers from the storage tank to the workstation.

Drum pump for filling battery acid.

A battery manufacturer uses several shades of acid to make the battery, the different types of acid are stored in sealed containers isolated in a room specially designed for this purpose.

Each tank feeds a specific network, which makes it possible to directly feed the filling machines with the appropriate shade of acid.

The filling nozzles are fitted with pressure switches which electrically control each motor of the drum pumps in the event of an increase in pressure.

high pressure turbines for drum pumps:

In a large number of applications the choice of the high pressure turbine profile is essential, generally to cope with a high output pressure of the empty drum pump.

This pressure can have several origins:

Fluid viscosity

If the fluid is viscous, the pressure drop in the delivery hose will be greater, for example.

Geometric discharge height

If the delivery head is high, the delivery pressure will be too.

Pumping of chlorine for the pre-oxidation of water before treatment with drum pumps

A company uses 1000l drums of chlorine (sodium hypochlorite), intended for the pre-oxidation of water before drinking water treatment.

In this application, chlorine is used to promote coagulation efficiency, reduce sludge odors, reduce the proliferation of algae.

For this chlorine barrel vacuum application, we have selected a barrel vacuum pump with a tube without mechanical seal, in PVDF.

The flow rate adjustment is possible with the use of the universal motor model for drum pump equipped with a variator. The final flow adjustment is made by gradually opening the injection gun.

Pneumatic barrel pump for supplying car wash gantry soap.

A washing gantry manufacturer wants to automate the supply of soap and additives to the washing station.

Soap and additives are stored in 200 l or 1000 l drums in a closed reserve next to the washing station, soaps and shampoos can vary in viscosity depending on the cleaning product suppliers.

For this application, the washing station builder has selected a pneumatic membrane drum pump, which will continuously supply the washing station:

When the washing station is operating, the Demar pneumatic drum pump automatically adapts its flow rate to the speed of the washing station.

In the event of a shutdown, the drum pump remains under pressure, does not consume energy, but remains nimble in operation.

The advantage of using this technique is that it does not disturb the soap too much to avoid foaming.

Pump for emptying liquid fertilizer drums:

In the agricultural world, the handling of chemicals can generate a number of safety problems during the handling phase.

Agricultural chemical fertilizers are mainly stored in 200l or 100l drums.

To prevent farmers from handling them dangerously, the use of a drum pump is recommended, in particular to secure the transfers between the storage tank and the tractor tank.

Laboratory drum pump.

Laboratories use a large number of fluids, these fluids can be used to be directly analyzed and studied or be used as a reagent for example.

In other cases laboratory fluids are used to clean, disinfect.

Most of these laboratory fluids are active and should be handled with care.

Laboratory drum pumps are generally smaller than standard industrial drum pumps and the flow rate can be easily adjusted to reduce risk

Drum pump for detergent

Detergents are chemical fluids frequently used in industry, for washing mechanical parts after machining, for example:

cutting oils used to facilitate the machining of parts must be cleaned.

The storage of these detergents is carried out with different container sizes, from 5l to 1000l.

Depending on the nature of the barrels selected, suitable empty cane heights of 700mm 1000mm or 1200 barrels can be used for 1000 l tanks.

The main types of detergent will be pumped with empty drum pumps with a polypropylene plunger.

How to choose a drum pump:

The choice of a drum pump is essential for the proper functioning of your installation, the important points for the choice of your drum pump:

determine the material of the elements in contact with the fluid, this choice and depending on the chemical compatibility of the materials with the fluid, the temperature of the fluid.

The tube length of the drum vacuum pump: the standard length is 1200mm, this length is suitable for the dimensions of the 200l and 1000l drums.

for other barrel volumes choose the length of rod closest to the size of the barrel.

Discharge flow and pressure:

Drum emptying applications are generally low pressure with a flow rate of around 80l / min.

Here, you have a more precise requirement, it is possible to choose a turbine promoting the flow rate up to 200l min or a turbine promoting the outlet pressure up to 3 bars.

Similarly, the viscosity of the fluid will guide the choice of the turbine profile:

the more viscous the fluid, the higher pressure turbine profile will be chosen.

Drum pump for acid

Acids are dangerous for people and installations, depending on the type of acid, the nature of the diver will be made with the most resistant material:

Hydrochloric acid: polypropylene or pvdf tube.

Nitric acid empty tube PVDF drums.

Sulfuric acid empty tube PVDF drums.

Chromic acid empty tube PVDF drums.

Hydrofluoric acid empty tube PVDF drums.

Phosphoric acid empty tube Polypropylene drums.

Drum pump for alkaline fluid

Alkaline fluids are fluids with a ph greater than 7.

These products, depending on their concentrations, can be extremely corrosive and must be handled with care.

Caustic soda is an alkaline compound widely used in industry, used to neutralize acids, for example.

Soda transfer:

vacuum pump for polypropylene barrels.

bleach :

Bleach is a basic solution more or less concentrated in active chlorine.

Pumping of very dilute bleach can be done with a polypropylene drum pump, in the most common cases of industrial use where the concentration of active chlorine may be higher, we recommend the use of a drum pump in PVDF.