PLASTIC PUMPS TFG800

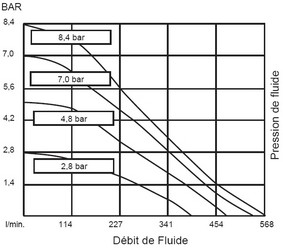

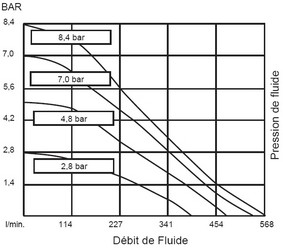

Techni-flow pump 2 "is a plastic pumps whose range is the largest,

in fact it has an impressive

power reserve of more 600l/mn maximum flow of water while maintaining proportions reasonable.

Among the many applications include

the cardboard to pump large quantities of glue and viscosities which is variable chemical aggressiveness.

The high flow rate of

the pump allows use centralized and can replace

many small pumps distributed on each machine.

Process reliability is

significantly increased

One

use of this range of pumps is to pump sludge wastewater treatment plant

plant industry.

Sludge pumped are generally corrosive and chemically aggressive over

their viscosity can be significant

The paper industry including

manufacturing industries use

large cardboard varieties

of adhesives viscosity and

chemical aggressiveness variable

diaphragm pneumatic pump

tfg800 with its large capacity is capable of

pumping fluids over10000cpo with high throughput

Peristaltic pumps range

The double diaphragm air

pumps Techni-flow provide an optimal response to

pumping problems most

diverse.

Due to low internal velocities, abrasive

fluids can be transferred

without damage to the air

pump. Similarly, fragile products are not subject

to deterioration due to

shear.

The pneumatic pump Techni-flow does not require output shaft seals or packing. The tightness of the pumped

product is ensured by gaskets and membranes. On the other hand, a building

with retention chamber

and leak detector in case ofdiaphragm rupture

is available for the

transfer of hazardous liquids.

Self-priming that occurs

just at the start of the pneumatic pump

without first filling.

The pneumatic pump Techni-flow can run dry without problems. Upon returning to a normal diet, the pneumatic pump returns to its

original rate.

The pressure of the air

motor balancing exactly the pressure of the liquid, the air pump

stops and restarts without damage when opening

the valve. It is not necessary to protect

the air pump by a valve

or a bypass.

Adjusting the flow rate of

0 to 100% of the maximum value

obtained by simply

adjusting the tap air.

The absence of thermal

or electric motor (pump tire is its own engine) can

have an air pump easily transportable and versatile

for a wide range of flow.

The supply of compressed

air from a pneumatic pump Techni-flow requires no

lubrication, allowing to avoid

any pollution of the

air by the values of oil